Introduction to axial contact bearings

Axial contact bearings are one type of thrust bearings in rolling bearings, and the other is angular contact bearings. Axial contact bearings are mounted perpendicular to the axial direction and can only withstand axial forces. A type of radial contact bearing relative to a radial bearing in a rolling bearing. There are two types of axial contact bearings: one is a ball bearing. The other type is the axial roller bearings.

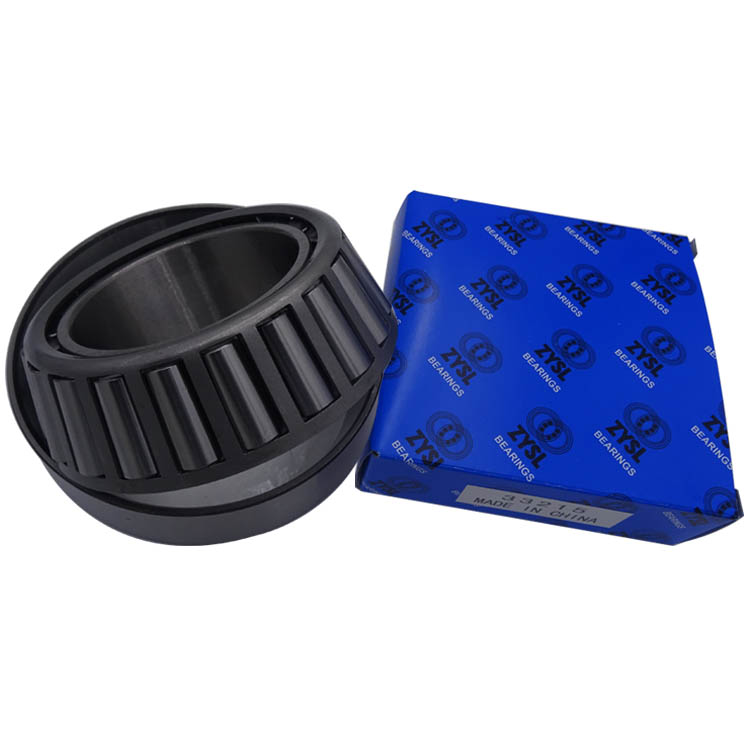

Now, let's learn about the axial roller bearings and their material.

According to the main criteria of the bearing working capacity, the material of the bearing should have the certain bearing capacity, embedding, thermal conductivity, low friction coefficient, smooth surface, anti-wear, anti-fatigue and corrosion resistance. No single material can fully satisfy all the requirements, which is why the compromise method is often used in most designs.

The following is a brief description of the performance and application of several bearing materials.

Bearing alloy

Bearing alloys (Babbitt) are widely used. They are usually available in two types: tin-based bearing alloys and lead-based bearing alloys, which have the characteristics of fast running and easy to smooth the surface. They are usually attached to the bearing base of the steel as a bearing liner. Babbitt bearings have good adaptability and are self-adjusting for smaller misaligned or defective shafts. Since the proper amount of dust or foreign matter entering the lubricant can be absorbed by the soft material to prevent gluing damage of the shaft, the embedding property makes them excellent bearing materials. The journal material can be mild steel, hard steel or cast iron.

Bronze

Bronze bearings are suitable for low-speed and heavy-duty applications where the shaft and bearing are moderately neutral. They can be made from a variety of alloy compositions to achieve a variety of physical properties.

Lead copper

The bearing capacity of this kind of bearing is higher than that of the bearing alloy, and its adaptability is poor, so it is used in the case where the rigidity of the shaft is good and the neutrality is good.

Cast iron

Cast iron axial roller bearings materials are widely used in applications where the requirements are not critical. The hardness of the journal must be higher than the stiffness of the bearing. The working surface should be carefully run with a blend of graphite and oil. It is required that the journal and the bearing must be well centered.

Porous bearing

The so-called "self-lubricating" or "porous" bearings can be made by first sintering the metal powder and then immersing it in oil. Bronze of various compositions is widely used on porous bearings with less iron. Due to the self-lubricating properties of porous bearings, it is mainly used in applications where it is difficult or impossible to obtain reliable lubrication when using general lubrication methods.

Carbon and plastic

Pure carbon axial roller bearings can achieve satisfactory results in high-temperature applications or when conventional lubrication methods cannot be used. Teflon is a very common plastic. The bearing made of it has a very low coefficient of friction and is used in the case of oil-free lubrication, it can work under low speed or intermittent swing and heavy load conditions. Experiments have shown that some combinations of materials work well together, while others do not. Excessive wear and tear in the combination of materials that do not work well together.

If you want to buy tapered bore bearings or other ball & roller bearings, if you are interested in our bearings, please contact me, we will do the best for you!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.