Con rod bearing is also called articulated bearing, its function is to transmit axial force and radial force.

Con rod bearing is divided into connecting rod big end bearing and connecting rod small end bearing. Connecting rod small end bearing is a connecting rod small end bearing that cooperates with piston pin or cross head pin to reduce pin wear. Often sliding bearings.

On the non-cross-head type connecting rod, the small end con rod bearing is usually made of tin bronze, lead bronze, or a steel sleeve with a friction reducing alloy on the inner surface. Oil holes are drilled on the inner surface of the bushing, and some are also made with oil grooves so that the lubricating oil enters the lubrication. In order to prevent dry friction when the diesel engine starts, some bearings have oil storage grooves on the inner surface.

A few small high-speed diesel engines use needle bearings for the small end bearings of connecting rods. On the cross-head connecting rod, the small end con rod bearing is a split sliding bearing, which is often made separately from the shaft. The friction-reducing alloy is directly cast on the inner surface of the bearing, and an oil groove is formed on the surface of the friction-reducing alloy. Oil holes for lubrication.

Since the small-end con rod bearing works under high pressure and swing conditions, it is difficult to lubricate. In order to improve the reliability of lubrication, some models use a special oil p ump for each cylinder to enhance lubrication. In order to improve working reliability, self-adjusting or platform type connecting rod small-end bearings are often used.

The big end con rod bearing is connected with the crank pin to reduce the wear of the crank pin. The big-end bearing of the connecting rod is a split sliding bearing.

The large-end bearing of the crosshead connecting rod is often made separately, and then the connecting rod bolt is fixed to the shaft body, and the antifriction alloy is often directly cast on the inner surface thereof. The large-end con rod bearing without a crosshead is usually made with the upper half of the shaft and the lower half of the bearing cover is made separately, and then fixed with the connecting rod bolt to the upper half, and on the bearing The inner surface of the lower half is equipped with bearing bushes.

For lubrication, oil holes are drilled on the con rod bearing of the big end, and oil grooves and garbage grooves are formed on the surface of the friction reducing alloy.

2

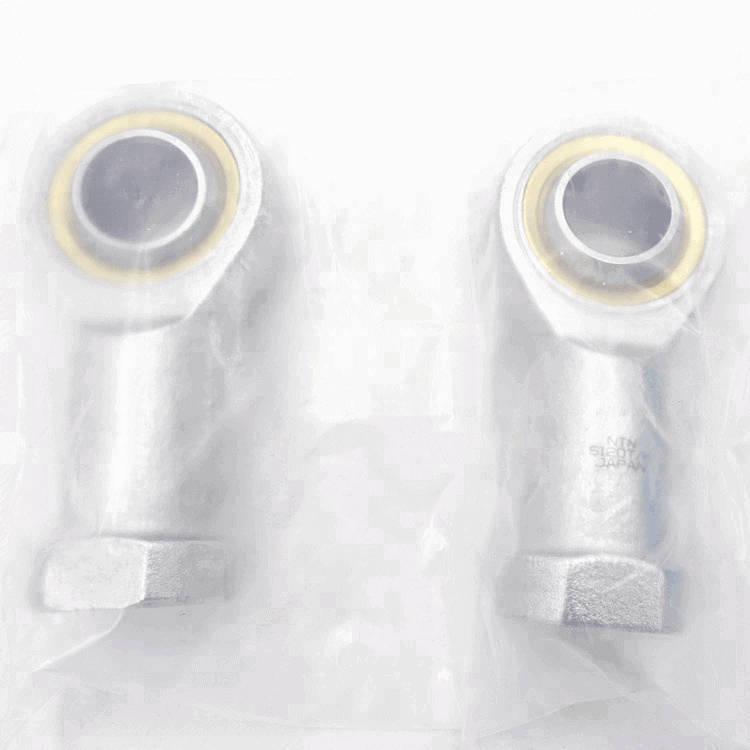

con rod bearing

1. Reason

(1) Poor lubrication or too small bearing clearance, causing the bearing alloy to burn out.

(2) The quality of the con rod bearing itself is defective, and the alloy falls off.

(3) The connecting rod journal is out of round, which reduces the contact surface between the journal and the con rod bearing, causing early loss.

(4) The con rod bearing and the journal are worn out too much, and the radial clearance between the two is too large.

(5) The fixing bolt of the con rod bearing cover is loose, or half of the fixing bolt of the connecting rod bearing cover is broken.

(6) Con rod bearing rotates relative to the bearing seat.

2. Check and judge

(1) When the gasoline engine slightly moves the throttle valve, you can hear the more complicated "groove, groove" sound; repeatedly start the throttle from idle to medium speed (open the large throttle test), the abnormal sound increases with the engine speed Increase and increase, and is particularly prominent at the moment of refueling.

(2) Observed from the fuel port of the machine, there is a strong "clang, clang" abnormal sound, with the aftertone of the sound of a wooden rod hitting the iron barrel.

(3) During the "fire-off" test, the abnormal noise obviously weakened or disappeared, and the instant the recovery of work, the abnormal noise recovered.

3

Little end con rod bearing

The big end con rod bearing is a split sliding bearing. The large-end bearing of the crosshead connecting rod is often made separately, and then the connecting rod bolt is fixed to the shaft body, and the antifriction alloy is often directly cast on the inner surface thereof.

For large-end bearings without cross-head connecting rods, the upper half of the bearing is often made integral with the shaft, while the lower half of the bearing cover is made separately, and then the connecting rod bolt is fixed to the upper half and the bearing The inner surface of the lower half is equipped with bearing bushes. For lubrication, oil holes are drilled in the large-end bearings, and oil grooves and garbage grooves are formed on the surface of the anti-friction alloy.

The small-end con rod bearing is a small-end bearing that is used with piston pins or cross-head pins to reduce pin wear. Often sliding bearings.

On the non-cross-head type connecting rod, the small end con rod bearing is usually made of tin bronze, lead bronze, or a steel sleeve with a friction reducing alloy on the inner surface.

Oil holes are drilled on the inner surface of the bushing, and some are also made with oil grooves so that the lubricating oil enters the lubrication. In order to prevent dry friction from occurring when the diesel engine starts, some con rod bearings are also provided with oil storage grooves on the inner surface. A few small high-speed diesel engines use needle bearings for the small end bearings of connecting rods.

On the crosshead connecting rod, the small-end bearing is a split sliding bearing, which is often made separately from the shaft. The friction-reducing alloy is directly cast on the inner surface of the bearing, and an oil groove and oil hole are formed on the surface of the friction-reducing alloy For lubrication.

Since the small-end con rod bearing works under high pressure and swing conditions, it is difficult to lubricate. In order to improve the reliability of lubrication, some models use a special oil pump for each cylinder to enhance lubrication. In order to improve work reliability, self-adjusting or platform-type small-end con rod bearings are often used.

Welcome to contact me to get the price of con rod bearing!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: +8618363031398

Wechat:18363031398

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.