Coupling connection with the crank pin to reduce the wear of the crank pin. The big-end bearing of the connecting rod is a split sliding bearing. The large-end bearing of the crosshead connecting rod is often made separately, and then the connecting rod bolt is fixed to the shaft, and the antifriction alloy is often directly cast on the inner surface. For large-end bearings without cross-head connecting rods, the upper half of the connecting rod bearing is often made integral with the shaft, while the lower half of the connecting rod bearing cover is made separately, and then the connecting bolt is used to fix the upper half and the The inner surface of the lower half is equipped with bearing bushes. For lubrication, oil holes are drilled in the large-end bearings, and oil grooves and garbage grooves are formed on the surface of the antifriction alloy.

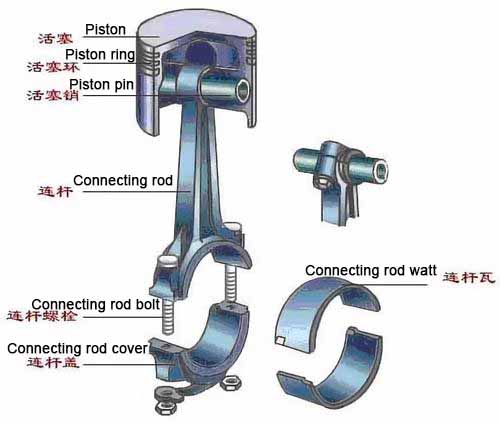

connecting rod bearing structure

Oil holes are drilled on the inner surface of the bushing, and some are also made with oil grooves so that the lubricating oil enters the lubrication. In order to prevent dry friction when the diesel engine starts, some bearings have oil storage grooves on the inner surface. A few small high-speed diesel engines use needle bearings for the small end bearings of connecting rods. On the crosshead connecting rod bearing, the small-end bearing is a split sliding bearing, which is often made separately from the shaft. The friction-reducing alloy is directly cast on the inner surface of the connecting rod bearing, and an oil groove and oil hole are formed on the surface of the friction-reducing alloy For lubrication. Because the small-end bearings work under high pressure and swing conditions, it is difficult to lubricate. In order to improve the reliability of lubrication, some models use a special oil pump for each cylinder to enhance lubrication. In order to improve work reliability, self-adjusting or platform type connecting rod small-end bearings are often used.

Link form

The main damage forms of connecting rod bearing are fatigue fracture and excessive deformation. Usually the location of fatigue fracture is the three high stress areas on the connecting rod. The working conditions of the connecting rod bearing require the connecting rod to have high strength and fatigue resistance; it also requires sufficient rigidity and toughness. In the traditional connecting rod processing technology, the material is generally quenched and tempered steel such as 45 steel, 40Cr or 40MnB, and the hardness is higher. Therefore, new connecting rod materials produced by German automobile companies such as C70S6 high carbon microalloy non-tempered steel and SPLITASCO series Forged steel, FRACTIM forged steel, S53CV-FS forged steel, etc. (the above are German din standards). Although alloy steel has high strength, it is sensitive to stress concentration. Therefore, strict requirements are required in the shape of connecting rods and excessive fillets, and attention should be paid to the surface processing quality to improve fatigue strength, otherwise the application of high-strength alloy steels will not achieve the expected results.

connecting rod bearing assembly

1. Press fitting connecting rod copper sleeve. It is best to use a press when installing the copper sleeve of the connecting rod, or use a vise to avoid slamming with a hammer; the oil hole or groove on the copper sleeve should be aligned with the oil hole on the connecting rod bearing to ensure its lubrication

2. Assemble the piston and connecting rod. When assembling the piston and connecting rod, pay attention to their relative positions and directions.

3. Cleverly install the piston pin. The piston pin and the pin hole have an interference fit. When installing, you should first put the piston in water or oil to evenly heat to 90 ℃ ~ 100 ℃, after taking out, put the rod in the appropriate position between the piston pin seat hole, and then install the piston pin coated with organic oil in the predetermined direction Into the piston pin hole and connecting rod bearing copper sleeve

4. Installation of piston ring. When installing the piston ring, pay attention to the position and order of the rings.

5. Install the connecting rod group.

Welcome to contact me to get the price of connecting rod bearing!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.