Features of ge spherical plain bearing

ge spherical plain bearing can withstand larger loads. According to its different types and structures, it can bear radial load, axial load or a combined load of both radial and axial. Because the outer spherical surface of the inner ring is inlaid with composite materials, the bearing can produce self-lubrication during operation.

ge spherical plain bearing is generally used for low-speed swing motion and low-speed rotation, and can also be tilted within a certain angle range. When the support shaft and the shaft shell hole are not concentric, it can still work normally. Self-lubricating joint bearings are used in water conservancy and professional machinery industries.

Application of ge spherical plain bearing

ge spherical plain bearing is widely used in engineering hydraulic cylinders, forging machine tools, engineering machinery, automation equipment, automotive shock absorbers, water conservancy machinery and other industries. ge spherical plain bearing is a spherical plain bearing. The basic type is composed of inner and outer rings with spherical sliding spherical contact surfaces. Depending on its structure and type, it can bear radial load, axial load, or a combined load that acts on both radial and axial directions.

Because the spherical sliding contact area of ge spherical plain bearing is large, the inclination angle is large, and also because most joint bearings adopt special processing methods, such as surface phosphating, galvanizing, chrome plating or outer sliding surface lining, inserting, spraying Therefore, ge spherical plain bearing has a large load capacity and impact resistance, and has the characteristics of corrosion resistance, wear resistance, self-aligning, good lubrication or self-lubricating without lubricating dirt pollution, and it can work normally even if the installation is misplaced. Therefore, joint bearings are widely used in low-speed swing motion, tilt motion and rotation motion.

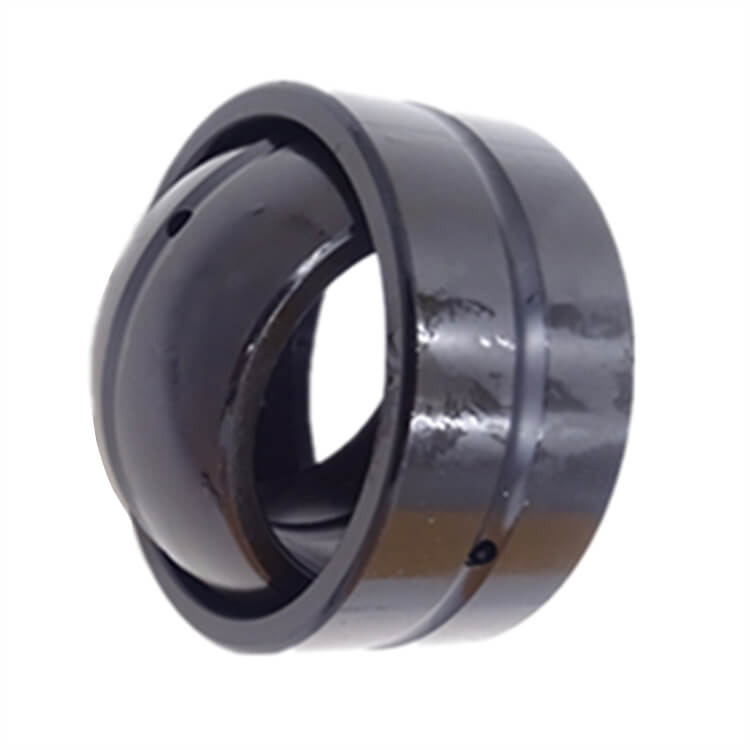

Composition of ge spherical plain bearing

ge spherical plain bearing is mainly composed of an outer ring and an inner ring. The inner spherical surface of the outer ring and the outer spherical surface of the inner ring form a rolling friction pair.

The performance of ge spherical plain bearing

Since the structure and working mechanism of the joint bearing are completely different from the rolling bearing, the joint bearing has its own technical characteristics and maintenance requirements.

ge spherical plain bearing working temperature

The allowable working temperature of the joint bearing is mainly determined by the matching materials between the sliding surfaces of the ge spherical plain bearing, especially the plastic sliding surface of the self-lubricating ge spherical plain bearing, its carrying capacity will decline at high temperatures. For example, when the sliding surface material of the lubricated ge spherical plain bearing is paired with steel/steel, the allowable operating temperature depends on the allowable operating temperature of the lubricant. But for all lubricating and self-lubricating joint bearings, they can be used within the temperature range of -30℃~+80℃ and maintain the correct bearing capacity.

The inclination of ge spherical plain bearing

The inclination angle of articulated bearings is much larger than that of general adjustable centering rolling bearings. It is very suitable for use in supporting parts with low concentricity requirements. The inclination angle of articulated bearings varies with the size, type, sealing device and support form of the ge spherical plain bearing. The inclination range of radial joint bearings is 3°-15°, the inclination range of angular contact joint bearings is 2°-3°, and the inclination range of thrust joint bearings is 6°-9°.

ge spherical plain bearing coordination

In any case, the selected fit of the joint bearing must not cause uneven deformation of the ring. The selection of the nature and grade of the fit must be determined according to the working conditions such as bearing type, supporting form and load size.

Loading and unloading of ge spherical plain bearing

The loading and unloading of the ge spherical plain bearing should follow the following principles, that is, the force applied by assembly and disassembly cannot be directly transmitted through the spherical sliding surface. In addition, auxiliary loading and unloading tools, such as sleeves, detachers, etc., should be used to directly and evenly apply the loading and unloading force exerted by the outside to the matched ferrule, or use auxiliary methods such as heating for loading and unloading without load.

Installation of ge spherical plain bearing

When assembling the joint bearing series, it is necessary to pay special attention to the position of the dividing surface of the outer ring. In order to prevent the load from directly acting on the dividing surface, it is necessary to maintain the dividing surface at right angles to the coincidence direction.

Lubrication of ge spherical plain bearing

When the load and the speed generated by the swing movement are very small, the oil-feeding ge spherical plain bearing can be operated without lubrication. Nevertheless, under normal circumstances, grease must be replenished regularly. During the initial installation and operation, it is recommended that the lubrication cycle be appropriately shortened.

Oil-free ge spherical plain bearing can be used without lubrication. However, if lithium soap-based grease is added before operation, the service life of ge spherical plain bearing will be extended. If grease is injected into the space around the bearing, the joint bearing will be more effective in preventing the intrusion of dust and foreign matter.

Welcome to contact me to get the price of ge spherical plain bearing!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: +8618363031398

Wechat:18363031368

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.