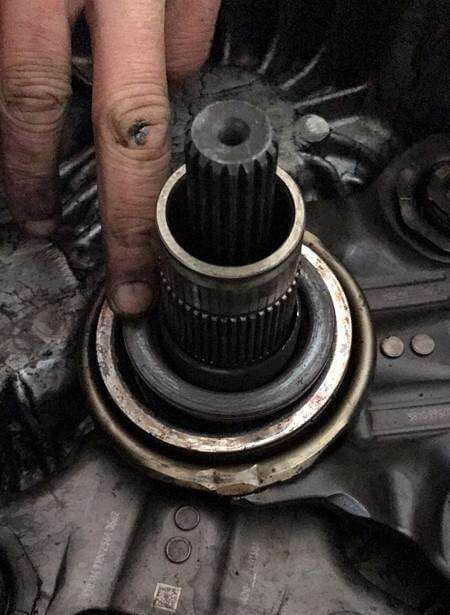

How to deal with the larger bore of gearbox bearing?

2,409

Published by

Mar 04,2020

Methods as below:

1. The outer ring of the gearbox bearing is electroplated or sprayed with metal, and the outer diameter of the bearing is processed to a value that matches the bearing hole.

2. For the matching position of the bearing hole and the bearing, manually twist the points, and then apply epoxy to the position, and then install the gearbox bearing. Do not use until the resin has cured and dried.

life:

Under a certain load, the number of revolutions or hours that a bearing experiences before pitting occurs is called the bearing life.

The life of a rolling gearbox bearing is defined in revolutions (or hours of operation at a certain speed): gearbox bearings within this life should undergo initial fatigue damage (flaking or defect) on any of its bearing rings or rolling elements.

However, whether in laboratory tests or in actual use, it can be clearly seen that the appearance of the same gearbox bearing under the same working conditions, the actual life is greatly different. In addition, there are several different definitions of bearing "life". One of them is the so-called "working life", which means that the actual life that a bearing can achieve before being damaged is caused by wear and tear, usually not caused by fatigue, but by Caused by wear, corrosion, seal damage, etc. In order to determine the standard of gearbox bearing life, the gearbox bearing life is related to reliability.

Due to differences in manufacturing accuracy and uniformity of materials, even if the same batch of gearbox bearings of the same material and the same size are used under the same working conditions, their lifespans are not the same. If the statistical life is 1 unit, the longest relative life is 4 units, the shortest is 0.1-0.2 units, and the ratio of the longest to the shortest life is 20-40 times. 90% of gearbox bearings do not cause pitting, and the number of revolutions or hours experienced is called the rated bearing life.

gearbox bearing dynamic load rating:

In order to compare the bearing capacity of the gearbox bearing against pitting corrosion, when the rated life of the bearing is specified to be one million revolutions (106), the maximum load that can be supported is the basic dynamic load rating, expressed as C.

That is, under the action of the rated dynamic load C, the gearbox bearing has a reliability of 90% when it works for one million revolutions (106) without pitting failure. The larger the C, the higher the bearing capacity.

Welcome to contact me to get the price for gearbox bearing!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: +8618363031398

Wechat:18363031398