1. Lubrication of linear ball slides

1) The role of linear ball slides lubricant

(1) Make the linear ball slides work as close as possible to the liquid friction state to reduce the frictional resistance, reduce the driving power, and improve the efficiency.

(2) Reduce the wear of linear ball slides and prevent corrosion of the guide rails. The flowing lubricating oil also acts as a flushing agent.

(3) Avoid creeping under low speed and heavy load, and reduce vibration.

(4) Reduce frictional heat at high speed and reduce thermal deformation.

2) Selection of lubricating oil for linear ball slides

Based on experience and data, the following factors are mainly considered when selecting the linear ball slides for machine tools.

(1) Lubricating oils for both hydraulic and linear ball slides. According to the needs of different types of machine guides, linear ball slides, which are also used as hydraulic media, meet the requirements of linear ball slides and hydraulic systems. For example, for a machine like a coordinate boring machine, the viscosity of the linear ball slides oil (50 ° C) should be chosen higher (40 ~ 90mm2 / s), but like various types of grinding machines, the linear ball slides oil is often supplied by the hydraulic system. However, the requirements of the hydraulic system are high and must be met. At this time, the viscosity of the hydraulic oil of the guide rail (50 ° C) should be selected lower (20 ~ 40 mm 2 / s), that is, the viscosity required for the hydraulic system.

(2) Select the viscosity according to the sliding speed and the average pressure.

(3) According to the actual application of linear ball slides lubrication at home and abroad. When choosing to use the guide rail lubricant, you can also refer to the example of the actual application of the linear ball slides of the existing domestic and foreign machine tools.

The linear ball slides of CNC machine tools usually use centralized oil supply and automatic drip lubrication. Domestic lubrication equipment XHZ series thin oil centralized lubrication device. The device is composed of a quantitative lubrication pump, a precision oil filter, a liquid level detector, a feed oil detector, a pressure relay, a progressive oil separator and a fuel tank. Regularly supply oil to the rail surface.

Solid lubrication is the application of a solid lubricant on the friction surface of linear ball slides to form a bonded solid lubricant film to reduce friction and reduce wear. There are many types of solid lubricants, which can be classified into metals, metal compounds, inorganic substances and organic substances according to basic materials. Add solid lubricant powder to the grease to enhance or improve the load bearing capacity, aging performance and high and low temperature performance of the grease.

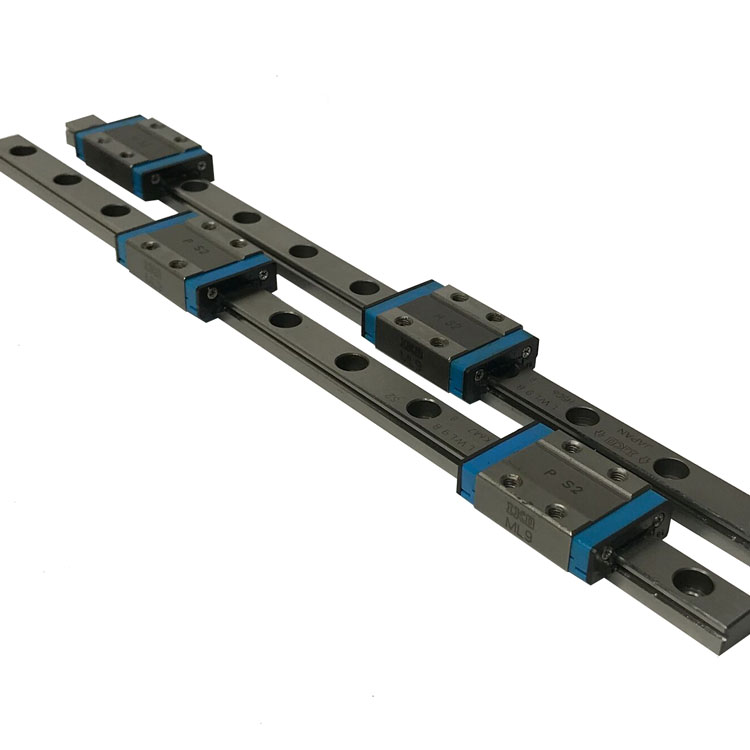

2. Linear ball slides protection

Linear ball slides protect against or reduce rail wear and extend rail life. The protective device is produced by a special manufacturer and can be purchased.

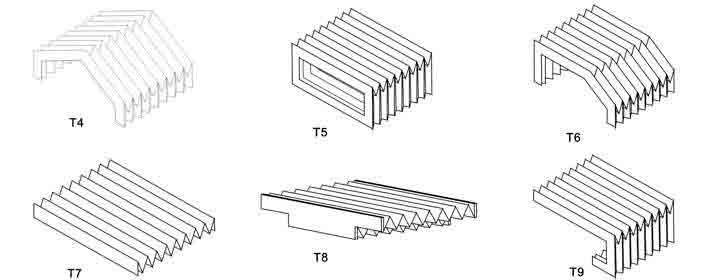

Linear ball slides have many protection methods, and the common shields are shown in the figure. CNC machine tools. Especially when cutting in the center, there are many iron filings and coolants, which are easy to enter the linear ball slides and increase the wear of the linear ball slides. When the iron filings are large, the lifting of the table affects the accuracy of the linear ball slides, so the steel plate is usually used. Telescopic shield.

ZYSL company specializes in nylon linear bearing for many years. All raw materials and accessories have been carefully selected to ensure a good user experience.

Welcome to contact me to know the price of nylon linear bearing!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: +8618363031398

Wechat:18363031398

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.