Just like all the bearing of the linear technology, sliding ball bearing and ball bearing these two fundamental differences exist between the same bearing type. In previous design, the selection of ball bearing is one of the main choice. Thanks to the innovative development of high-performance engineering plastics, now sliding bearing can work normally without a need for lubrication, especially suitable for some applications with special requirements.

Working principle of the rolling bearing and sliding ball bearing

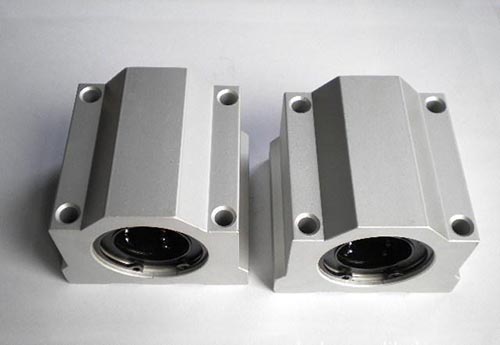

Engineering plastic sliding bearing in a straight line and drive technology as a result of the sliding ball bearing technology advantage will be diagram to illustrate.

Surface pressure, because of the large contact area is more smaller, and you can use soft shaft axis or other materials, such as aluminum alloy, carbon fiber, etc., so the sliding ball bearings is one of the many advantages of further reduce weight.Because there is no hard friction parts for mechanical rolling, also does not have the rolling body collide with each other, so the sliding operation noise and vibration will be less.

Use linear sliding ball bearing, the guide rail can be joining together, which can easily form a long trip, the reason is that the movement of the sliding element easier than scrolling through the guide rail joint.All ball bearings and related materials of a major disadvantage is that allows the velocity and acceleration constraints, the maximum value is limited, especially in low load.

Engineering plastic sliding ball bearing, by contrast, has high sliding speed and acceleration, thus greatly improve the cycle time in many applications. But the most important trump card is its service life, bearing made of high-performance engineering plastics are usually want to be more durable than traditional ball bearing. In addition, its service life can be through a variety of programs to calculate. In the past few years, both accuracy and friction values have made great progress. Before using traditional ball bearing has now started to use in a broad range of areas, engineering plastic sliding shaft.

Welcome to contact me to get the price of sliding ball bearing!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.