Stainless steel deep groove ball bearings are mainly distinguished from ordinary bearings by corrosion resistance. Other aspects are similar. If the environment is acidic and corrosive, it is recommended to choose stainless steel deep groove ball bearings, and their service life is definitely better than ordinary bearings.

Bearing steel generally has a high carbon content and enhances wear resistance, while stainless steel deep groove ball bearings generally have a high Cr content of more than 12%, mainly for utilizing its corrosion resistance. Compared with ordinary bearings, stainless steel deep groove ball bearings not only have obvious advantages in material, but also in process, the precision of stainless steel deep groove ball bearings is much stricter than that of ordinary bearings.

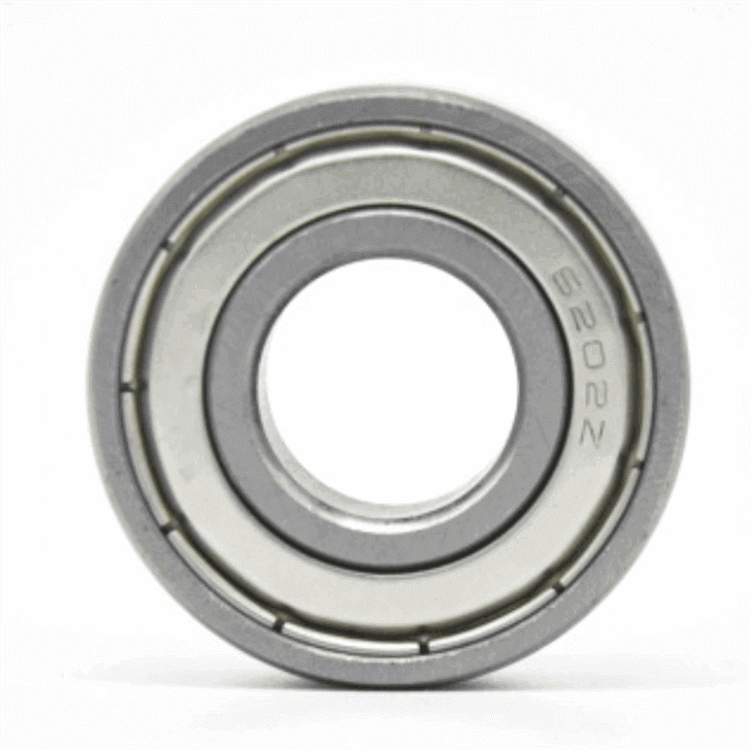

Stainless steel deep groove ball bearings work stably, with low noise, corrosion resistance and wide application. Stainless steel deep groove ball bearings and rolling elements are made of AISI SUS440C stainless steel, vacuum-quenched and tempered, and the cage and seal frame materials are made of AISI 304 stainless steel.

Compared with ordinary bearing steel, stainless steel deep groove ball bearings have stronger rust and corrosion resistance. Choose suitable lubricants, dustproof covers, etc., and can be used in the environment of -60 ° C ~ +300 ° C. Stainless steel deep groove ball bearings are resistant to corrosion caused by moisture and several other media.

This type of single stainless steel deep groove ball bearings has the same deep bearing groove as the standard deep groove ball bearing made of carbon chromium (rolling bearing) steel. The degree of fit between the bearing race and the ball is extremely high. Stainless steel deep groove ball bearings are widely used in food processing, medical equipment, and pharmaceutical machinery due to their high mechanical strength and load capacity.

If you need double row deep groove ball bearing or other bearings, please contact me any time!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: +8618363031398

Wechat:18363031398

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.