do you know the analysis of thin section angular contact bearings for industrial robots?

2,657

Published by

Sep 16,2019

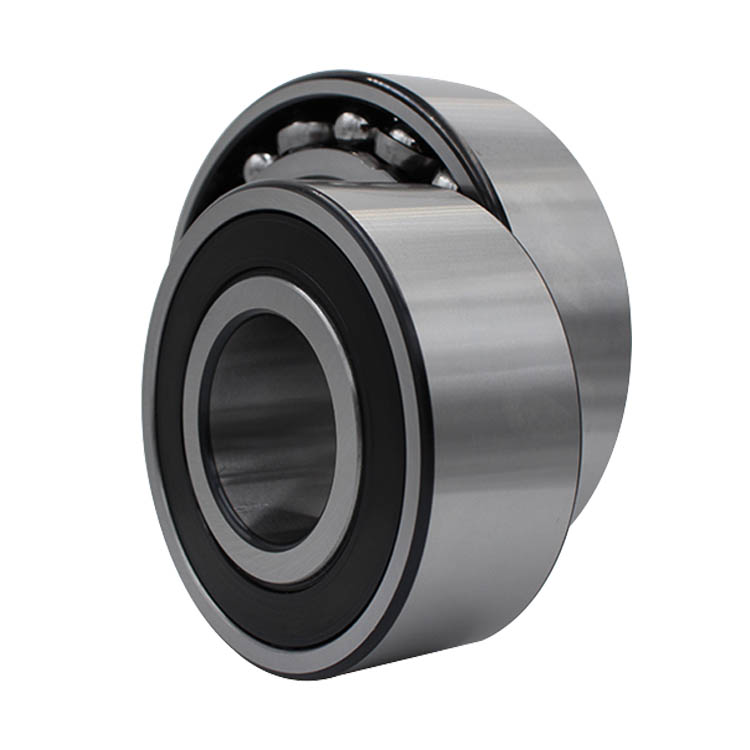

In recent years, with the development of advanced manufacturing, the demand for various types of robots representing modern manufacturing technology is increasing. Such as large-scale construction machinery, automobiles, home appliances and other automated production lines, as well as deep-sea manned submersibles, humanoid bionic robots and painting, arc welding, spot welding, assembly, and handling industrial robots that enhance the national high-tech strategic position. The special bearings for the robot's key components have an important impact on the key performance indicators such as the smooth running of the robot, repeated positioning accuracy, motion accuracy and reliability of the work. Because thin section angular contact bearings and wall cross-roller bearings have the characteristics of strong combined load capacity, high precision, low friction torque, light weight and stable operation, they are mostly used in the waist, elbow and wrist of industrial robots. Department and other parts.

(1) The comparison between the outer diameter and the inner diameter is small, the diameter of the rolling element is small, and the number is large. Compared with the standard bearing of the same inner diameter, the weight is about 5% of the standard thin section angular contact bearings, and the cross-sectional area is about 20% of the standard bearing.

(2) Fixed-section bearings: thin section angular contact bearings series, the bearing cross-section dimensions are the same, and do not change with the change of inner and outer diameter.

(3) It can withstand radial load, bidirectional thrust load and overturning moment, which are equivalent to two sets of angular contact ball bearings installed back to back, but the width is only equivalent to the width of a set of angular contact ball bearings.

1. Design of key structural parameters

According to the use condition of thin section angular contact bearings in robots and the requirements of long life, high rigidity and low friction, it is necessary to consider not only the maximum rated dynamic load but also the cross-section of thin section angular contact bearings. Small features, we must carefully select the optimal value of each structural parameter to improve the contact stress distribution of the bearing parts, to achieve the best contact state for the formation of lubricating oil film, and to improve the service life of the bearing.

2, the ferrule channel position

Since the inner and outer rings of the thin section angular contact bearings adopt an integral structure and the cross-sectional area is only 20% of the same inner diameter standard thin section angular contact bearings, the radial wall thickness of the cage is limited. If the universal bearing is used, the channel position is designed in the bearing. At the center of the width, the bearing forms a symmetrical structure, the strength of the bottom of the cage hole will be affected, and the installation position of the sealing ring will also be limited. Therefore, in order to ensure sufficient strength of the bearing cage and sufficient installation space of the sealing ring, the groove The position takes asymmetrical design on both sides of the end face.

3, the determination of the height of the rib

When the thin section angular contact bearings of the industrial robot is in operation, it is subjected to a certain axial load in addition to a certain radial load. When the axial load is applied, a contact ellipse will be formed between the steel ball and the raceway. If the axial load is too large, the steel ball may contact the edge of the inner and outer rings or the contact ellipse between the rib and the raceway. It is cut off, resulting in stress concentration, causing fatigue wear of the thin section angular contact bearings ring and early failure. Therefore, when the rib height is designed, the minimum rib height J of the bearing ring is calculated according to the Hertz contact stress theory according to the axial load of the thin section angular contact bearings, and the diameter of the ferrule rib is calculated. In the actual design, the cross-sectional area of the four-point contact ball bearing is small, and the wall of the ferrule is thin. Under the premise of meeting the requirements of use, the value of the rib height coefficient is smaller than that of the deep groove ball bearing.

4, sealing structure design

Industrial robots are moving toward miniaturization, weight reduction, and precision. Therefore, the lubrication of bearings for industrial robots is preferably lubricated by means of a lubrication with a sealing structure. The sealing performance of the thin section angular contact bearings is one of the important indicators to measure the sealed thin section angular contact bearings. The early damage of the sealed bearing is often caused by the poor bearing seal and the gradual failure of the pollutant entering the thin section angular contact bearings. Therefore, when designing a sealed bearing, the sealing mating pair should be safe and reliable, and the specific working requirements of the thin section angular contact bearings and the specific structural form of the bearing must be taken into consideration.

ZYSL company specializes in thin section angular contact bearings for many years. All raw materials and accessories have been carefully selected to ensure a good user experience.

Welcome to contact me to know the price of thin section angular contact bearings!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563