What's the Difference Between types of bearings?

All types of bearings square measure wont to facilitate cut back friction. Metal-upon-metal contact produces giant amounts of friction. The friction adds to wear and tear of the metal, manufacturing grinding that slowly degrades the metal. Bearings cut back friction by having the 2 surfaces roll over one another, reducing the quantity of friction made. They carries with it a swish metal ball or roller that rolls against a swish inner and outer metal surface. The rollers or balls take the load, permitting the device to spin.

The load acted upon an impact is either a radial or thrust load. looking on the placement of the bearing within the mechanism, it will see all of a radial or thrust load or a mix of each. for instance, the bearing within the wheel of your automotive supports a radial and a thrust load. the load of the automotive on the bearing produces a radial load where as the thrust load is made because the automotive turns a corner. Here we are going to examine some forms of common bearings.

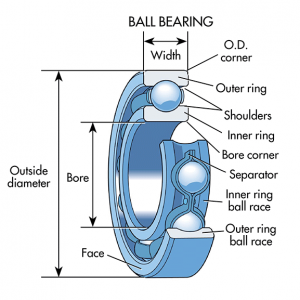

Ball types of Bearings

Ball types of bearings area unit most typical sort of bearing and might handle each radial and thrust hundreds. Ball bearings also are called deep-groove single-row or author bearings. The inner ring is often fixed to the shaft and also the groove on the outer diameter provides a circular ball raceway. The outer ring is mounted onto the bearing housing. The ball bearings area unit housed in a very race and once the load is applied, it's transmitted from the outer race to the ball and from the ball to the inner race. The raceway grooves have typical curvature radii of fifty one.5% to fifty three of the ball diameter. Smaller curvature raceways will cause high rolling friction thanks to the tight conformity of the balls and raceways. Higher curvature raceways will shorten fatigue life from accumulated stress within the smaller ball-race contract space.

1.Ball types of bearings, conjointly called author types of bearings, area unit usually employed in little load applications.

The contact points between the ball and also the outer race is incredibly little thanks to the spherical form of the bearing. This conjointly helps the ball spin terribly swimmingly. Since the contact purpose is thus little, the bearing will become overladen at a particular purpose inflicting the roller bearing to become ill-shapen. this may ruin the bearing. Ball bearings area unit usually employed in applications wherever the load is comparatively little.

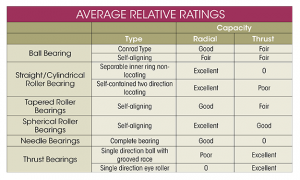

2.The table higher than lists some general forms of ball types of bearings and their typical load capabilities.

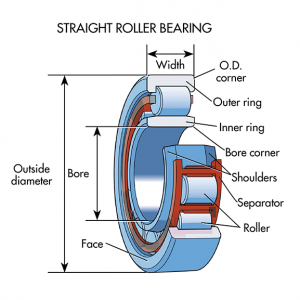

Straight Roller types of Bearings

Straight roller or cylindrical types of bearings run in cylindrical raceways and have low-friction, high-radial load capability, and high speed capability. Roller bearings area unit cylinder-shaped bearings wherever the purpose of contact between the bearing and also the race could be a line instead of a degree. Load is distributed over a bigger space and permits the bearing to handle a larger load. to reduce its tendency to skew, the roller’s length isn't a lot of larger than the diameter of the roller.

3. Straight or cylindrical roller types of bearings will be found in applications like conveyor-belt rollers, that area unit needed to carry serious radial hundreds.

Their usual style is liberal to float axially, and that they have roller-guiding flanges on facets of 1ring and none on the opposite side. this enables for the bearing to expand thanks to thermal activity once employed in combination with a ball bearing’s fastened location at the other finish. A thrust load will be supported in one direction if a guiding projection is accessorial on one amongst the opposing rings’ aspect. A second projection will be accessorial for two-directional thrust capability.

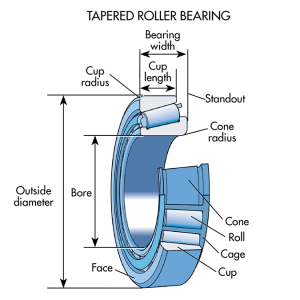

Tapered Roller types of Bearings

4. Tapered roller types of bearings area unit designed to face up to a radial and thrust load, and might be found in automotivehubs owing to the number of radial and thrust hundreds they will carry.

In tapered needle types of bearings, the rings and also the rollers area unit tapered within the form of truncated cones to at the same time support axial and radial hundreds. The magnitude relation of the hundreds depends on the angle of the axes between the roller and bearing. The larger the angle is that the larger axial load are often supported. The contact angle for many tapered roller bearings vary is between ten to sixteen degrees. For higher thrust-load capability, a 30-degree contact angle is employed.

5. Tapered types of bearings area unit mounted pairs since they handle radial hundreds higher than one row of tapered bearings. For heavy-duty applications, 2 or four rows of tapered rollers area unit combined in a very single unit in massive bearings.

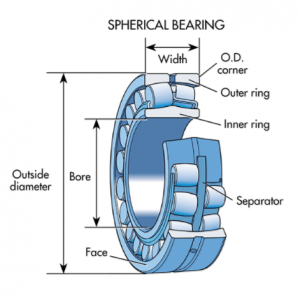

Spherical Roller types of bearings

Spherical roller types of bearings usually accommodates 2 rows of barrel-shaped rollers running in 2 raceways. One is on the inner ring and also the alternative is on endless spherical surface ground on the inner diameter of the outer ring. this enables the bearing to control with some arrangement. Spherical rollers have barrel profiles that closely match the raceways profiles, thence creating them sturdy and having a high load capability. they're mounted in pairs within the bearing housing and are long-faced in opposite directions. this is often done so the load can be supported in either direction.

6.Spherical roller types of bearings square measure employed in automobile hubs and might support massive radial and thrust hundreds.

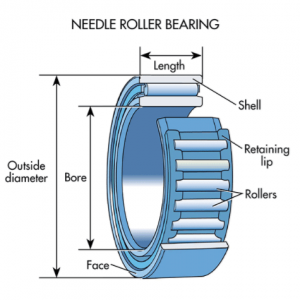

Needle Roller types of bearings

Needle roller types of bearings use elongated cylindrical rolling parts with tiny diameters. they're employed in applications wherever radial house is restricted. The diameter to length quantitative relation for the needles varies between 1-to-2.5 and 1-to-10. thanks to their tiny size, they can not be target-hunting accurately and generate high amounts of friction. they're used at low speeds and periodic motions as a result. Cages could also be wont to facilitate guide the needles and improve retention.

7. Needle roller types of bearings square measure employed in styles that have serious house restrictions.

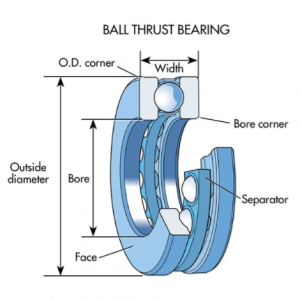

Thrust types of bearings

Designed to handle high thrust hundreds, roller-thrust types of bearings square measure usually found in gearsets used for automobile transmissions between gears or between the housing and rotating shafts. The angular teeth found in turbinate gears employed in automobile transmissions manufacture a high thrust load that's supported by the roller-thrust bearings. Roller-thrust bearings slide among a roller-race contact to handle the surface-speed variation that comes as a results of the varied diameter across the contact zone.

8. Ball thrust types of bearings square measure designed to handle virtually completely thrust hundreds in low-speed, low-weight applications. associate example of its use would be in bar stools wherever they're wont to support the seat.

Ball-thrust types of bearings square measure comprised of 2 grooved plates with a collection of balls between them. The ball-race contacts have a slippery action that's magnified at high speeds by the force on the balls. Cylindrical roller thrust bearings square measure restricted to concerning 2 hundredth of the speed of its radial bearing counterpart and ball-thrust bearings square measure restricted to half-hour of the speed of their counterpart.

All specifications and all brand and all types of bearings are in large ready stocks.

If you need,please contact me any time!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: +86 18363031398

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.