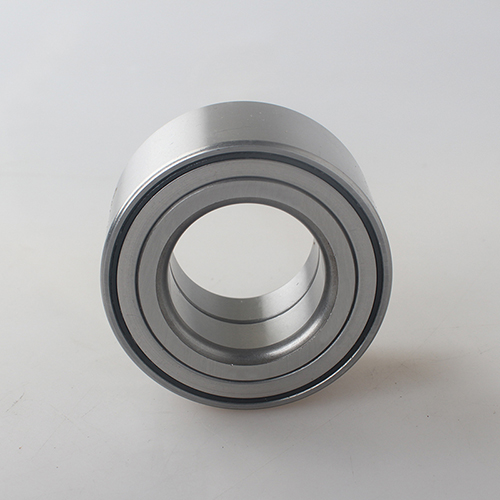

The development history of all balls wheel bearings

There is always a historical process for the existence of a thing, and the same is true for wheel bearings. Parts of products will also be constantly updated and iterated to adapt to various machine applications.

Hub bearings are developed on the basis of the other two types of bearings, namely tapered roller bearings and standard angular contact ball bearings. These two sets of bearings are integrated to make it light in weight, large in load capacity, and assembly performance. Good, compact structure, can omit clearance adjustment, omit the advantages of external wheel hub density, etc., at the same time, this also determines that it will be widely used in auto parts.

Daily maintenance of all balls wheel bearings

The wheel bearing maintains the important task of driving the car and is responsible for reducing the frictional resistance of the chassis when it is running. Routine maintenance is definitely indispensable. Once the hub bearing fails, the most direct cause will cause noise, bearing heating and other phenomena.

Disassemble of all balls wheel bearings

1. Remove the decorative cover and dust cover of the hub axle head;

2. Remove the tire but do not damage the thread of the tire bolt. If it is a disc brake, remove the brake, and then remove the lock ring or lock pin with a tool.

3. Use special tools to remove the hub bearing;

4. Clean up the old grease, clean it with detergent, then dry it with a cloth, and finally wipe the inner cavity of the bearing with a cloth.

5. Check the all balls wheel bearings and the bearing race. If there are cracks, fatigue peeling and loose bearing rollers, the bearing should be replaced. If pitting is found on the bearing race, the bearing should also be replaced.

6. Check the fit between the inner diameter of the bearing and the journal. The fit clearance should not be greater than 0.10mm. When measuring the journal, it should be measured at the upper and lower parts of the vertical ground (the place is the largest wear part). If the fit gap exceeds the specified limit of use, the bearing should be replaced to restore the normal fit gap. Burrs and pits on the journal are not allowed to narrow the gap.

7. After all the parts meet the requirements, the inner shaft coated with grease can be put into the hub.

8. Pay attention when applying grease. The amount of application is also required. It needs to be applied from one end of the all balls wheel bearings to the other side of the bearing until it comes out. However, do not apply too much in the cavity.

9. Reinstall the hub and outer shaft on the shaft diameter, screw on the shaft head adjustment nut by hand, and then use the shaft head wrench to tighten the adjustment nut according to the specified torque. After tightening the nut, you should turn the hub a few turns left and right to see the installation of the bearing; on the other hand, the bearing and the seat ring should be correctly matched by turning. At this time, the bearing tightness is appropriate, and the wheel rotates freely without feeling the axial clearance.

10. Finally, install the lock piece, fixing nut, tire, dust cover and decorative cover in sequence.

11. After adjusting the wheel hub bearing, drive for a certain mileage (about 10km), stop and check the temperature of the wheel hub with your hands. If it gets hot, it is caused by the over-tightening of the bearing. It should be re-adjusted to loosen the all balls wheel bearings tightness appropriately.

Welcome to contact me to get the price of all balls wheel bearings!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.