C2 C3 C4 bearings clearance is the gap between the bearing rolling elements and the inner and outer ring shells of the bearing. The so-called C2 C3 C4 bearings clearance refers to the amount of movement when the bearing is not installed on the shaft or the bearing box, the inner ring or outer ring is fixed, and then the bearing clearance is not fixed to move radially or axially . According to the direction of movement, it can be divided into radial clearance and axial clearance. The size of the clearance (called the working clearance) during operation has an impact on the bearing's rolling fatigue life, temperature rise, noise, vibration and other properties.

The role and requirements of C2 C3 C4 bearings clearance: The clearance in the bearing is to ensure that the bearing can run flexibly and without hindrance, but at the same time it is also required to ensure that the bearing runs smoothly, the axis of the bearing does not significantly sink, and the number of rolling elements that bear the load as much as possible. Therefore, the bearing clearance has a great influence on the dynamic performance (noise, vibration and friction) of the bearing, the rotation accuracy, and the bearing capacity of the service life (wear and fatigue).

Bearing internal clearance refers to the total distance of radial movement of one bearing ring relative to another (radial internal clearance) or the total distance of axial movement (axial internal clearance).

Working clearance refers to the clearance under the actual operating conditions of the bearing.

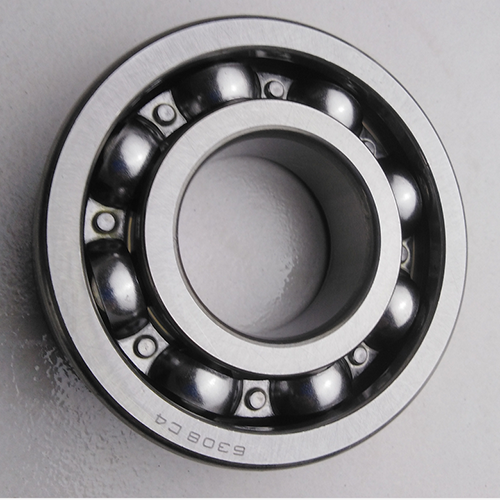

The original clearance refers to the clearance before the bearing is installed. The clearance value is divided into three groups according to the size, one group is the basic group (or the normal group), the small clearance group (C2), and the large clearance group (C3, C4 bearings).

Another example of daily application:

Under normal working conditions, the basic group should be selected first;

C3 and C4 bearings are suitable for the large interference between the inner and outer rings, or the large temperature difference between the inner and outer rings, the deep groove ball bearing needs to bear a larger axial load or need to improve the alignment performance, or need to increase the bearing limit speed and reduce the bearing Occasions such as friction torque

C2 is suitable for occasions with higher rotation accuracy, strict control of the axial displacement of the housing hole, and the need to reduce vibration and noise.

When measuring the clearance of a bearing, in order to obtain a stable measurement value, a prescribed measurement load is generally applied to the bearing.

Therefore, the measured value obtained is larger than the real clearance (called the theoretical clearance), that is, the elastic deformation caused by the measured load is increased.

But for roller bearings, since the amount of elastic deformation is small, it can be ignored.

The internal clearance of the bearing before installation is generally expressed by the theoretical clearance

Welcome to contact me to get the price of spherical plain bearing ge!

Contact: Ellen

Email: [email protected]

Skype: +8618668909563

MP/Whatsapp: +8618668909563

Wechat:18668909563

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.