Design of NNF double row cylindrical roller bearing sleeves locking and rolling device

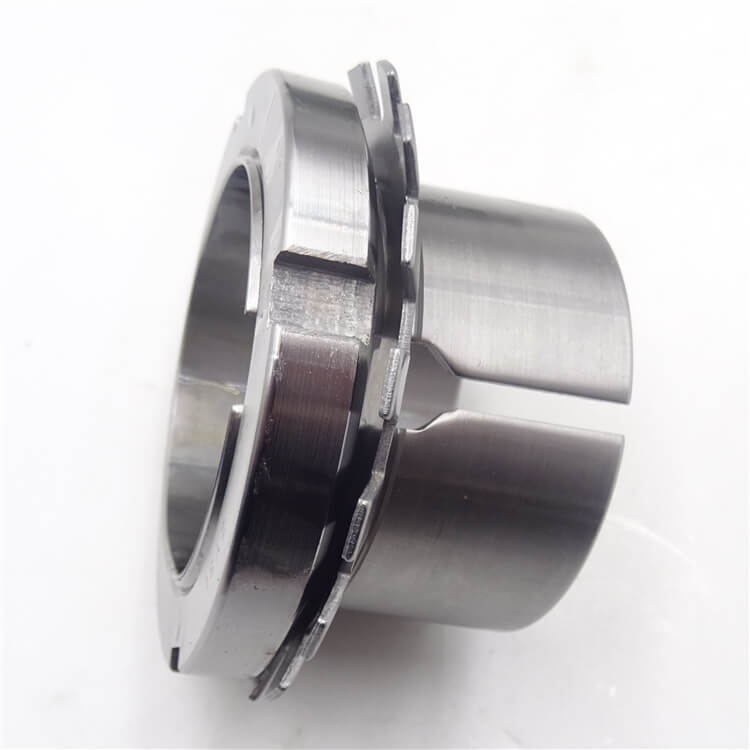

Abstract: For the split structure of NNF double-row column roller bearing, the locking die sleeve assembly is designed to rotate the mold sleeve and the work piece on the lathe. The special mold is directly formed by the pressure of the roller, and the bearing parts are tight. The joints are fixed together. The NNF double row cylindrical roller bearing adopts an outer ring with a middle rib and a split structure of two double rib inner rings. The rolling element is axially guided by the inner ring rib. The outer ring surface has two retaining grooves. It is axially positioned with contact seals on both sides. The two inner rings are fixed together by an inner locking ring (fastening ring) and are not separable. In addition to being able to withstand large radial and axial loads, the structure can withstand overturning moments and is therefore often used as a fixed bearing.

1. There are problems:

The sub-bearings are designed according to the design requirements, and finally the roller bearing sleeves are installed. After the inner roller bearing sleeves is directly rolled and formed by a special mold, the inner rings are locked, so that the inner roller bearing sleeves are tightly connected together to ensure that the radial fit is not loose. The components of the bearing shall be closely matched according to the requirements of the installation, and the inner roller bearing sleeves shall be installed under the condition that the inner end faces of the two inner rings are in full contact. The rolling process is one-time forming, and the special mold cannot be installed repeatedly. The bearing is a split structure, and the relative positions of the components are easily changed. It is difficult to install the inner ring without taking measures.

2 solutions:

The two inner ring assemblies can be axially tilted (because the outer ring has no outer ribs) before the inner roller bearing sleeves is fixedly locked, and the bearings can also be offset in the radial direction. In the case of the existing equipment, in order to ensure the positioning of the bearing when the roller bearing sleeves is locked, a special positioning locking die roller bearing sleeves is designed, and the locking roller bearing sleeves is composed of a locking jaw, a platen positioning screw and a fastening screw. In order to compact the forming, the rolling wheel is designed according to the characteristics of the inner ring and the inner locking ring. The outer shape of the roller and the groove on the inner diameter of the inner ring are assembled according to the assembly process. The outer ring of the bearing, the rolling element, the inner ring and the special mold are assembled, and the locking roller bearing sleeves is sleeved.

Uranium bearing: In order to avoid damage to the outer diameter of the outer ring of the bearing by the positioning screw, the positioning screw head is aligned with the outer diameter oil groove, and the screws at the outer diameter are tightened so that the locking clamp is fixed to the bearing of the bearing outer ring locking die roller bearing sleeves. Placed on the lathe chuck (so that the inner and outer end faces of the bearing are in full contact with the lathe chuck), the outer ring of the bearing and the locking die sleeve are integrated, and the inner ring is relatively movable, only the three claws of the lathe are clamped outside the outer ring of the bearing. The pre-locked bearing can be fixed in diameter. After determining that the bearing is fixed on the lathe table, the locking die roller bearing sleeves is pressed by the four fastening screws to make the pressure plate contact the end surface of the inner ring of the bearing, and the screw is tightened to press the inner ring under the action of the fastening screw. After the completion of the above work, the bearing components are fixed and loose, and the inner end faces of the two inner rings are completely in contact, achieving the expected effect of the design.

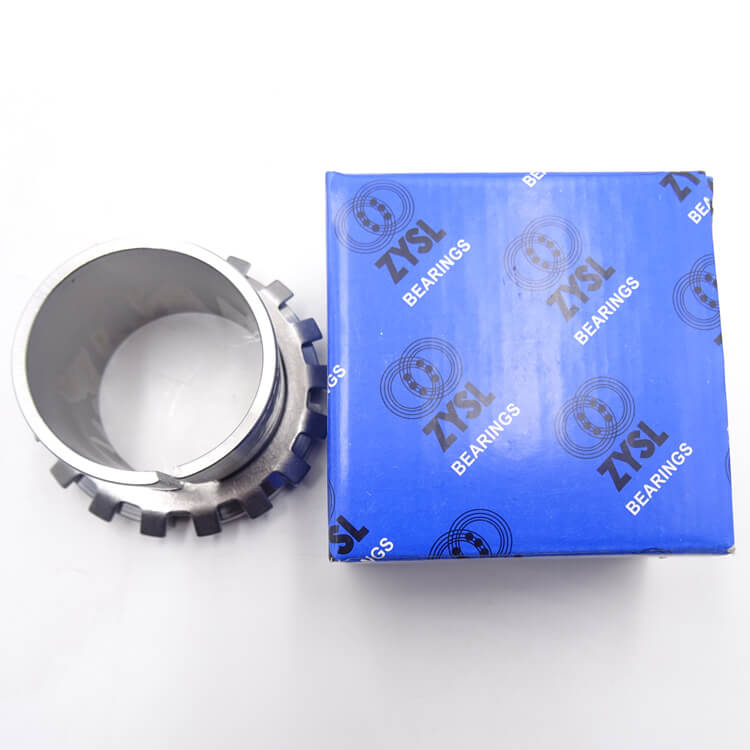

If you want to buy roller bearing sleeves or any other bearings, please contact me, we will do the best for you!

Contact:Miya

Email:[email protected]

Skype:[email protected]

MP/Whatsapp: +8618363031398

Wechat:18363031398

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.