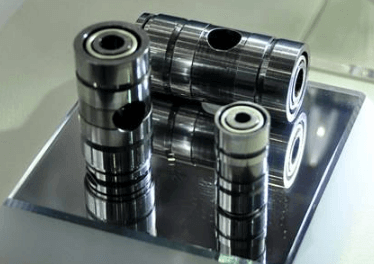

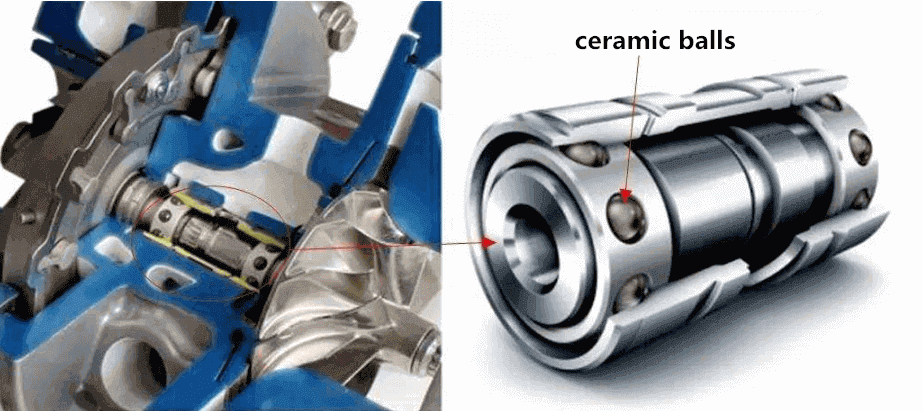

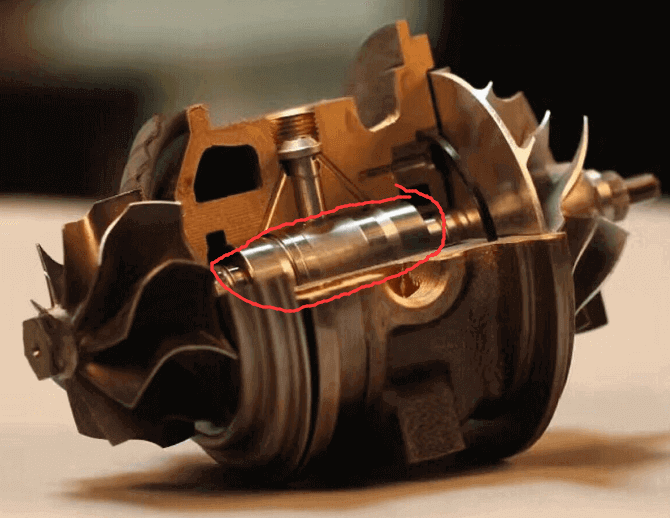

Turbocharger bearings include deep groove ball bearings, cylindrical roller bearings, pairs of double angular contact bearings and special pairs of double angular contact ball bearings.

Deep groove ball turbocharger bearings and cylindrical roller turbocharger bearings mainly bear radial load and have a high limit speed.

Paired double angular contact ball turbocharger bearings can bear radial and axial loads at the same time, and the axial displacement is small. For bearings requiring higher speed and greater load, the cage material is made of alloy steel, and the surface is specially treated.

How to install turbocharger bearings

1. After removing the turbocharger bearings, remove the bolts on both side covers and remove the side covers.

2. After removing both side covers, hoist the bearing seat horizontally with a crane. Use the wooden square to hold the center of the shaft, and then shake the bearing housing to hit the wooden square with the shaft to separate the shaft and turbocharger bearings from the bearing housing.

3. After separation, put the shaft and the bearing vertically on the place with a sledgehammer to smash the damaged two turbocharger bearings diagonally to separate them from the shaft, and take out the retaining ring between the two disk bearings, the inner retaining ring and the outer retaining ring.

4. Slightly heat the inner sleeve of cylindrical roller turbocharger bearings with acetylene oxygen to remove it from the shaft.

5. Use a wooden square and a sledgehammer to separate the cylindrical roller turbocharger bearings from the bearing housing until the bearing is disassembled. Clean the shaft, bearing seat and bearing with gasoline.

6. Put the two disc angular contact radial ball turbocharger bearings, the inner retaining ring between the bearings, the spacer sleeve and the inner outer jacket of the cylindrical roller bearing that need to be heated into the boiling oil pot in turn. The oil can be used in engine oil or gear oil. To ensure no impurities, heat for 10-5 minutes.

7. First put the inner sleeve of the heated cylindrical roller turbocharger bearings on the shaft, and after it cools, turn the shaft upright and install the heated turbocharger bearings on the shaft, then put the inner and outer retaining rings on the shaft in turn After it cools, install another ball bearing on the shaft.

8. After the turbocharger bearings have cooled down, install the centrifugal disc and tighten it with bolts. Use a crane to lift the bearing seat vertically and place it on the ground, and use a crane to vertically lift the shaft into the bearing seat.

9. Put copper rods or wooden squares on the turbocharger bearings, use a sledgehammer to hit the turbocharger bearings diagonally around the circumference to smash the bearings into the bearing seat, level the positions of the bearing and the bearing seat, then install the side cover and tighten the bolts.

10. Turn the bearing seat upside down and smash the cylindrical roller turbocharger bearings into the bearing seat in the same way as in the ninth step. Then put the oil-heated outer spacer sleeve on the shaft to cool down and tighten the bolts on the side cover.

Welcome to contact me to get the price of turbocharger bearings!

Contact: Miya

Email: [email protected]

Skype: [email protected]

MP/Whatsapp: +8618363031398

Wechat:18363031398

Double row angular contact ball bearing installation is more complex than deep groove ball bearin...

Failure reason of micro miniature bearing About 40% of the failure of micro miniature bearings i...

Novice Mistakes 1: Do not consider the characteristics of your own actions, blindly choose Althou...

When assembling cnc machine bearings, the Venus machine tool must be preloaded, so that the origi...

Performance characteristics of stainless steel self-aligning ball bearing Self-aligning ball bear...

The long board has a strong sense of operation and is quick to get started. The longboard is a mu...

The tapered thrust bearing with cage is a split design so that the two washers as well as the rol...

Disassembly of the tapered needle bearing: When the bearing is to be used continuously after it i...

TEL: +86 183-6303-1398

E-mail: [email protected]

E-mail: [email protected]

Whatsapp: +8618668909563

Whatsapp: +8618363031398

ADD: Room E3-1203, Mingquanchunxiao, Dikou Road, Tianqiao District, Jinan City Shandong Province, China.